Situation

Choosing an automation solution to handle increased demand and shorter lead times has become increasingly common. For many stakeholders, this involves significant investments to meet their growth and profitability goals in both the short and long term. A well-designed automation solution with associated processes and workflows often has an efficiency effect of approximately XX% (varies depending on the industry and product range). The significant potential often makes the business case very appealing while simultaneously addressing many operational challenges associated with strong growth.

Challenge

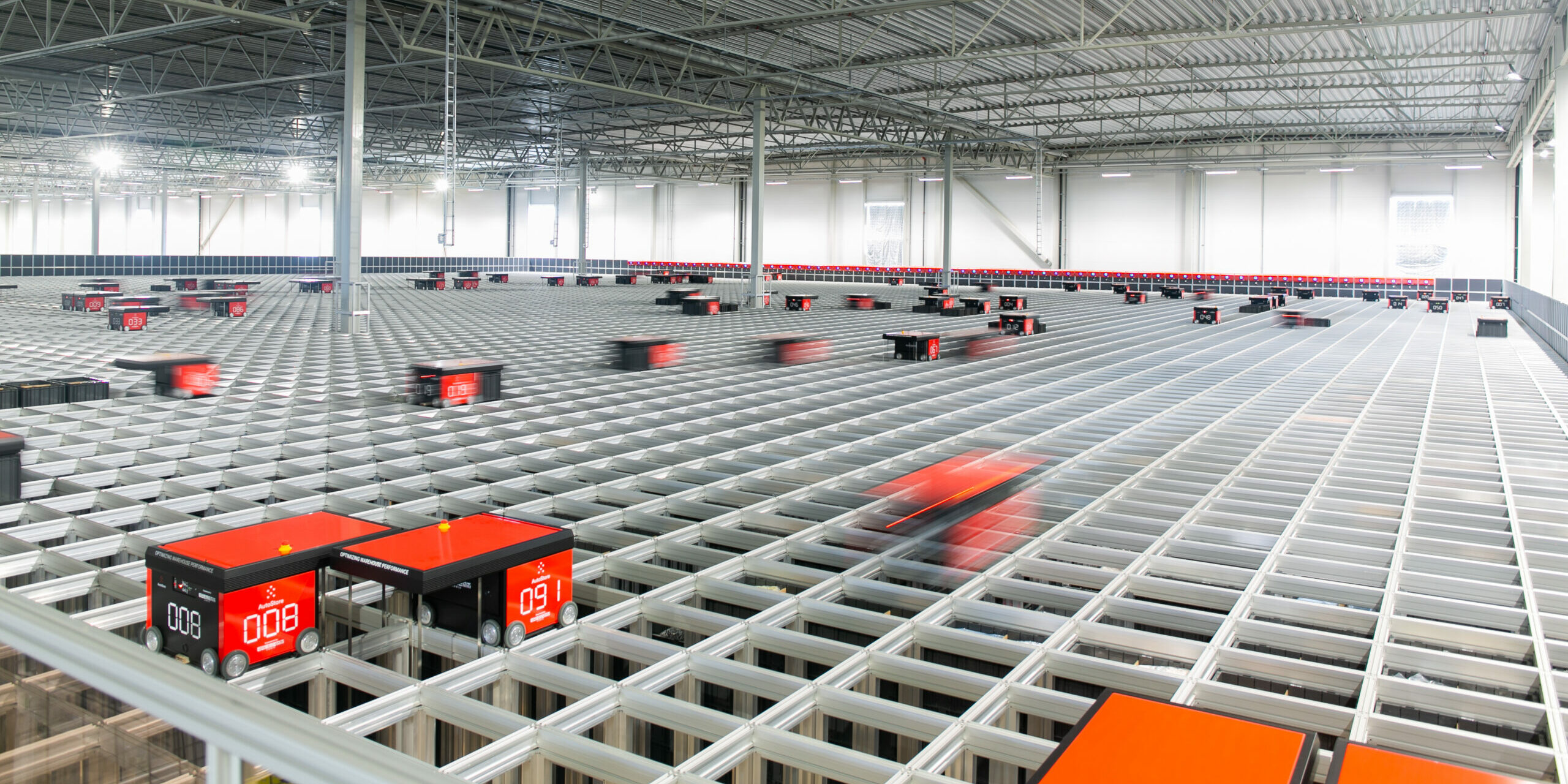

The transition from completely manual warehouse management to, for example, running larger portions of one’s assortment through an Autostore should not be underestimated. Many stakeholders have encountered significant challenges in even meeting the promised efficiency goals from automation suppliers, and the tuning period can often extend over several years before reaching that point. Another challenge is maintaining stability in KPIs and following patterns of variation. Many stakeholders who have achieved their promised efficiency in normal operations with reasonably stable volumes quickly see declining productivity figures during major volume deviations, such as Black Friday or holiday periods when commerce often declines.

The transition to automated warehouses has significant upsides and, if managed correctly, preceded by adequate analysis and planning, process and workflow design can yield fantastic productivity figures with increased profitability levels that manual handling could never achieve.

Logent’s Experience

Logent has extensive experience in analyzing, designing, implementing, and operating most automation solutions on the market. The accumulated experience from all parts of the process has led us to possess unique knowledge to achieve as optimal operational patterns as possible. Achieving efficiency figures of around 80% over time as a market player is not uncommon, but fine-tuning processes, workflows, and picking patterns to achieve even the last few percentages is often challenging and requires significant understanding. In several cases, Logent has successfully operated its facilities at very high productivity levels over time and also managed large volume variations while maintaining efficiency.